Seven Segment Display (SSD) is commonly used in counters, electronic meters, digital clocks, etc.

It is composed of 8 LEDs, 7 of the LEDs are arranged in rectangular form to display numbers from 0-9 and also characters A-F. The 8th LED is for decimal point display.

There two types of SSD:

- Common Cathode.

- Common Anode.

In Common Cathode, all the cathode of the diodes are connected to a common pin. while in Common Anode, all the anode are connected to a common pin.

Segments are marked with a-g

Each diode is treated separately, that is : when connecting it to a microcontroller, each diode must have its own limiting resistor. For you to display numbers or characters on SSD, the binary format of each digit must be replaced with different combination of bits (masking). For instance to display 2, which is 0000 0010 in binary it is replaced with 0110 1101.

Here is a look up table for displaying 0 - F on a common cathode SSD.

By sending this numbers one after the other to the PORT where the SSD is connected, you have a counter from 0 - F .

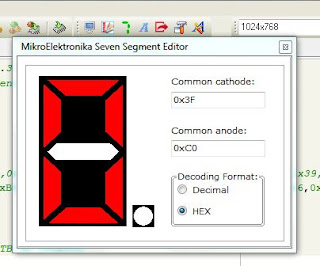

MikroC has SSD Editor which you can use to get this numbers for both common Cathode and Common Anode. On the Tool Bar click on the 7 symbol and it will pop up.

MikroC Code:

/**********************************

Project Name :

Interfacing of 7 segment display with PIC 16F877A

Author : Promise

Description :

This project demonstrate how to interface 7 segment display with PIC 16F877A. it counts from 0 - F

Test configuration:

MCU: PIC 16F877A

Oscillator: XT 8.0000 MHz, 8.0000 MHz Crystal

Dev Board : Easy Pic v7

turn on switches SW4.0, SW4.1, SW4.2, SW4.3

For common Cathode 7 segment display, Uncomment count1[16]

***********************************/

unsigned int i;

//unsigned int count1[16] = {0x3F,0x06,0x5B,0x4F,0x66,0x6D,0x7D,0x07,0x7F,0x6F,0x77,0x7C,0x39,0x5E,0x79,0x71}; //array for common cathode display (0-15)

unsigned int count[16] = {0xC0,0xF9,0xA4,0xB0,0x99,0x92,0x82,0xF8,0x80,0x90,0x88,0x83,0xC6,0xA1,0x86,0x8E}; //array for common anode display (0-15)

void main() {

TRISB = 0x00; //Configure PORTB as Outputs

while(1) {

for(i=0;i<16;i++){ // loop through array element

PORTB = count[i]; // send arrray elemnts to PORTB

delay_ms(500);

}

}

}

Proteus Schematic for Common Anode:

Proteus Schematic for Common Cathode: